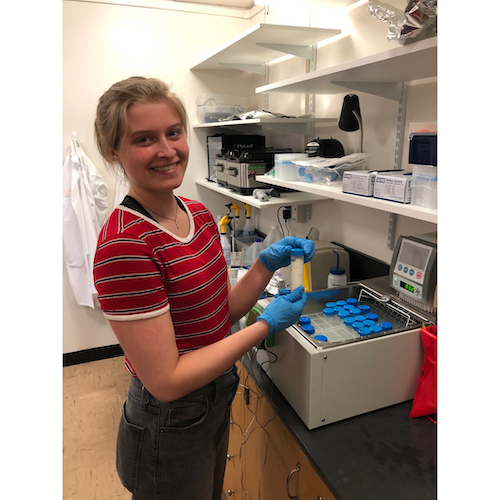

This week we have Andrea Domen, a MS student in Food Science and Technology co-advised by Dr. Joy Waite-Cusic and Dr. Jovana Kovacevic, joining us to discuss her research investigating some mischievous pathogenic microbes. Much like an unwelcome dinner guest, food-bourne pathogens can stick around for far longer than you think. Andrea seeks to uncover the mechanisms that allow for Listeria monocytogenes, a ubiquitous pathogen found in dirt that loves cheese (who doesn’t?), to persist in dairy processing facilities.

Listeria hysteria

Way back in the early 2000s, there were two listeriosis outbreaks that were linked to cheese. Because of these two outbreaks, the British Columbia Centre for Disease Control conducted a sampling program over the course of a decade. From this program, 88 isolates of L. monocytogenes from five different facilities were recovered. Within this set of isolates, 63 were from one facility which is now (perhaps unsurprisingly) shut down. Those 63 microbes were essentially clones of each other, which means this one lineage of microbes seemed to carry something that allowed them to survive for multiple years. So how did that lineage of Listeria survive? Turns out, like a 1990’s Reebok, they pump it. Listeria uses a protein in its cell membrane called an efflux pump to remove harmful chemicals like sanitizers, antibiotics, and heavy metals from the cell. Essentially, when the cell absorbs something that is too spicy – it’ll yeet it back out.

Don’t cry over contaminated milk

The idea that food borne pathogens are evolving to withstand processing environments is alarming, but fret not, the results of Andrea’s research are a first step to avoiding the creation of these super microbes in the first place. Instead, it can serve as a warning story for dairy production facilities about what can happen when L. monocytogenes contamination isn’t properly handled. In healthcare, it’s not uncommon to treat a microbial pathogen with multiple medications – as becoming resistant to several treatments is harder for the microbe than becoming resistant to just one. We are also able to apply this treatment method to sanitizing food production facilities by combining different sanitizers – but that is best left up to the chemists to avoid accidentally making an explosion or lethal gas.

To hear more about how Listeria can survive better than Destiny’s Child be sure to listen live on Sunday, May 7th at 7PM on 88.7FM, or download the podcast.