Trade Journal Articles

Scientific Journal Articles

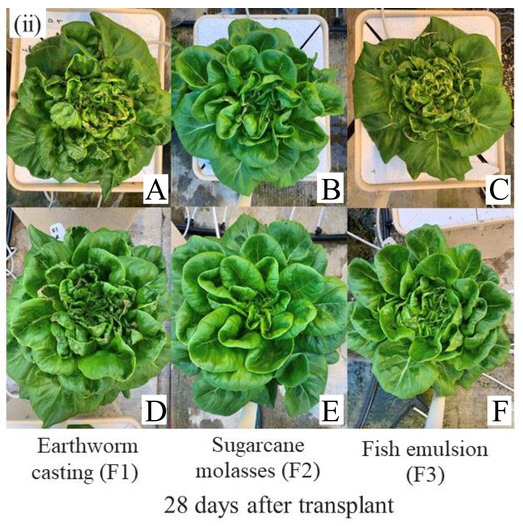

By: Parker Egan Persons, Marc W. van Iersel, Susanne Ullrich, Jie Zhan, Tu Anh Ngo, Tho Duc Nguyen, Paul M. Severns, Rhuanito Soranz Ferrarezi

HortSci: Volume 151: Issue 2 1

By: Lauren E. Kurtz, Alyssa J. Siegel-Miles, Mark H. Brand, Victoria H. Wallace

HortTech: Volume 36: Issue 1

By: Carter Miller, Herika Paula Pessoa, Seth Wannemuehler, Brandon Miller

HortTech: Volume 36: Issue 1

By: Martine Bowombe-Toko, Jason B. Oliver, Michael R. Allen, Douglas L. Airhart

JEH: Volume 40: Issue 4

Trade Journal Articles

Scientific Journal Articles

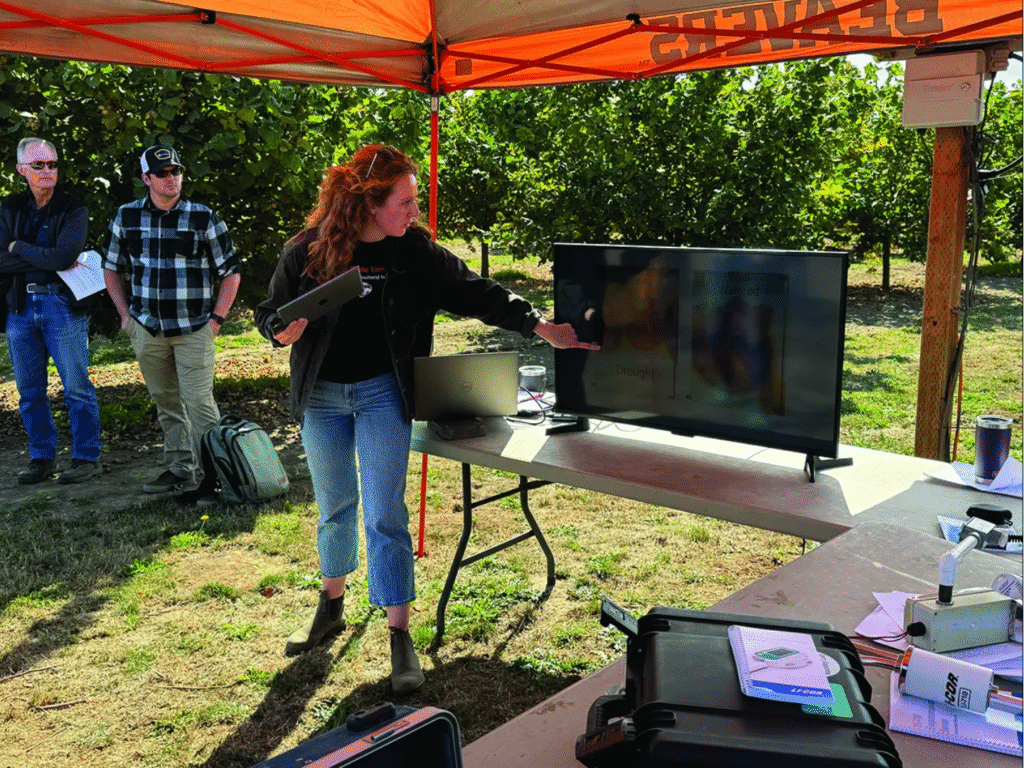

By: Lloyd Nackley, Dalyn McCauley, James Owen, Jr., Jacob Shreckhise, and Jeb Fields

Agriculture Volume 15: Issue 21

By: Amelia Keyser-Gibson, Lloyd Nackley, Youping Sun, Jared Sisneroz, Darren Haver, Ryan Contreras, Ursula K. Schuch, Lorence Oki, and Soo-Hyung Kim

Plants People Planet

By: Jill Edmondson, et al

Plants People Planet

By:Zheng Li, Tong Lyu, and Yingmin Lyu

Horticulturae Volume 10

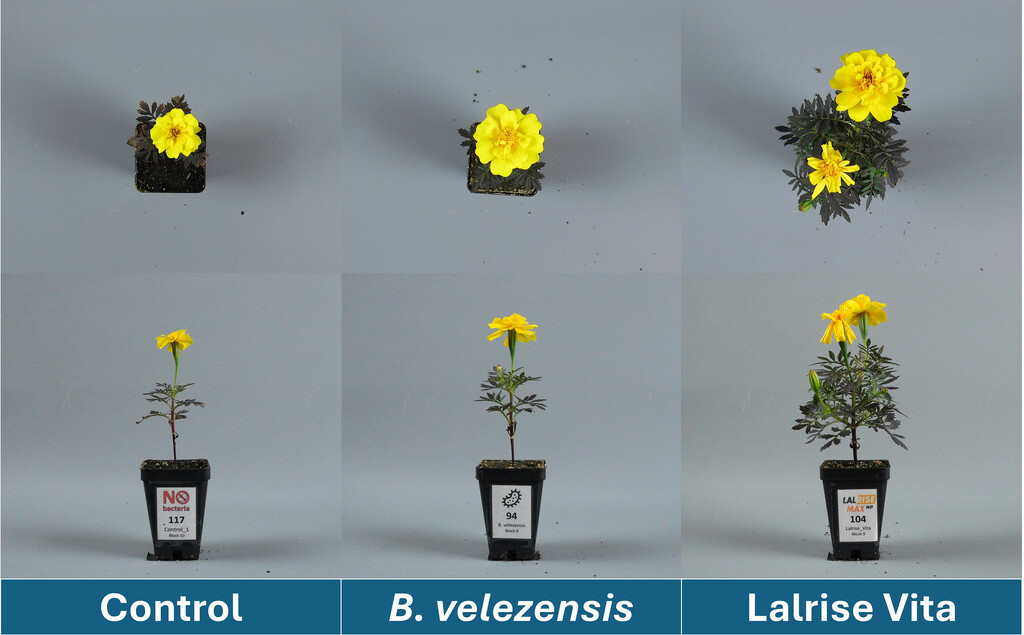

By: Livia M. S. Ataide, German Vargas, Yisell Velazquez-Hernandez, Marcello De Giosa, Isamar Reyes-Arauz, Paola Villamarin, Maria A. Canon, Simon S. Riley, and Alexandra M. Revynthi

Agriculture Volume 15: Issue 21

Below, we’ve curated the latest news and insights from trusted sources across the industry. Stay updated with these key highlights.

Trade Journal Articles

Scientific Journal Articles

By:Anne J. Knerr, Robert R. Tripepi, Armando G. McDonald, Senay Ugur

HortScience Volume 60: Issue 11

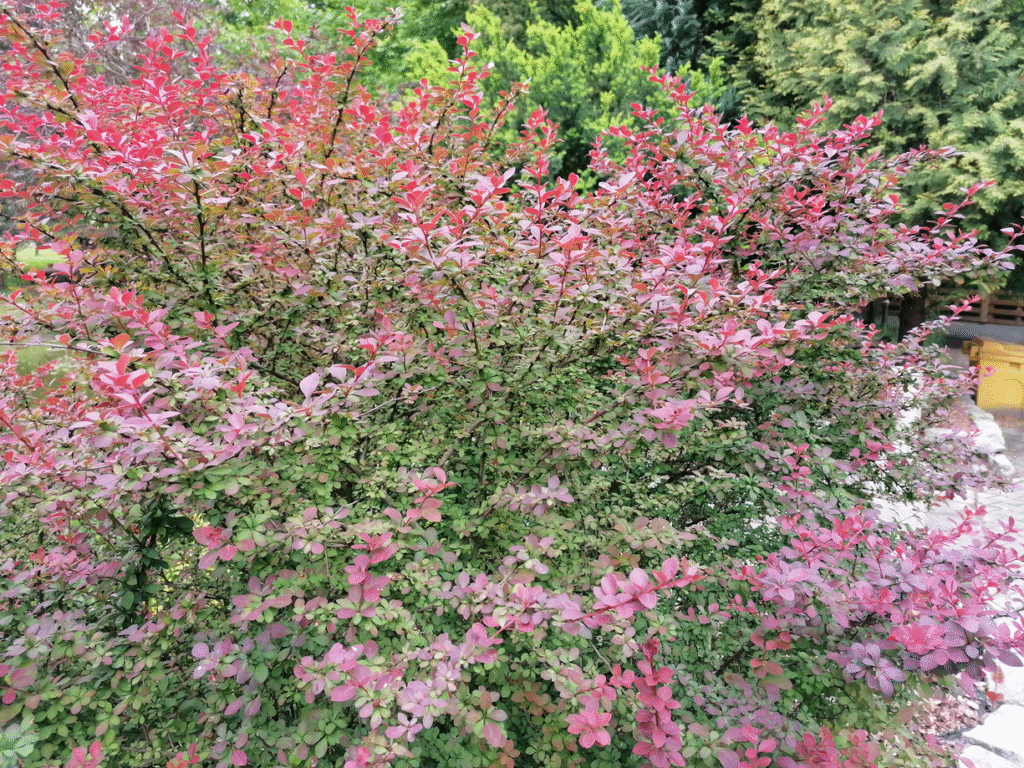

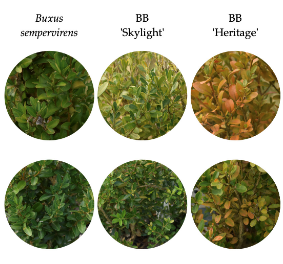

By:Ivana Šafránková, Jiří Souček, Marie Machanderová, Petr Salaš, Jana Burgová, Ludmila Holková

Horticulturae Volume 11

By:Ryan N. Contreras, Thomas G. Ranney, Sandra B. Wilson, John Lambrinos, Nathan P. Lynch, Acer VanWallendael, Richard T. Olsen, Mark Brand, Neil O. Anderson, John M. Ruter

Journal of Environmental Horticulture Volume 43: Issue 3

By: Yuvraj Khamare, Heather Kalaman, Chris Marble

Journal of Environmental Horticulture Volume 43: Issue 3

Below, we’ve curated the latest news and insights from trusted sources across the industry. Stay updated with these key highlights.

Trade Journal Articles

Scientific Journal Articles

By: Emily R. Stamm, Melanie C. Hill, Paul C. Bartley III, Sushil Adhikari, and M. Soledad Peresin

HortScience Volume 60: Issue 10

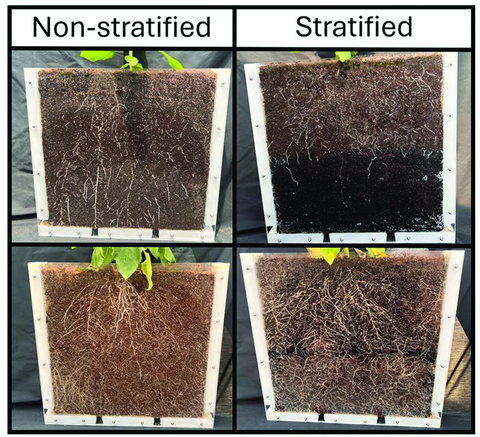

By: Austin Lindquist, Jeremy Pickens, Bernardo Chaves-Cordoba, Rishi Prasad, Eve Brantley, Glenn Fain, and Paul Bartley

HortScience Volume 60: Issue 10

By: Bo Lu, Yucheng Jiang, Ting Zhou, Xinran Chong, Xiaoqing Lu, Yunlong Li, Chuanyong Wang, Xiaolong Cai, Donglin Zhang, and Hong Chen

HortScience Volume 60: Issue 10

Below, we’ve curated the latest news and insights from trusted sources across the industry. Stay updated with these key highlights.

Trade Journal Articles

Scientific Journal Articles

By: Julie H. Campbell, Sheri Dorn, Natalie Bumgarner, Heather Kirk-Ballard

HortScience Volume 60: Issue 9

By: Berni M. van der Meer, Jack P. Solomon, Chantelle A. Kostanowicz, Martin Williams

Plants , People, Planet

By:Mehdi Sharifi, David Ensing, Masoumeh Bejaei, Rishi Burlakoti, Samir Debnath, Thomas Forge, Jordan Fraser, Kirsten Hannam, Janick Lorion, Jesse MacDonald, Chandra Moffat, Tyler Nelson, Hao Xu

Plants , People, Planet

Below, we’ve curated the latest news and insights from trusted sources across the industry. Stay updated with these key highlights.

Trade Journal Articles

By: Jeff Stone / Digger May 2025

Scientific Journal Articles

By: Wendy Hoashi-Erhardt, Patrick P. Moore, Michael A. Hardigan, Mary Peterson, Scott Lukas, Patrick Jones, and Michael Dossett

HortScience Volume 60: Issue 6

By: Patrick Veazie, Hsuan Chen, Kristin Hicks, Jennifer Boldt, and Brian Whipker

HortScience Volume 60: Issue 6

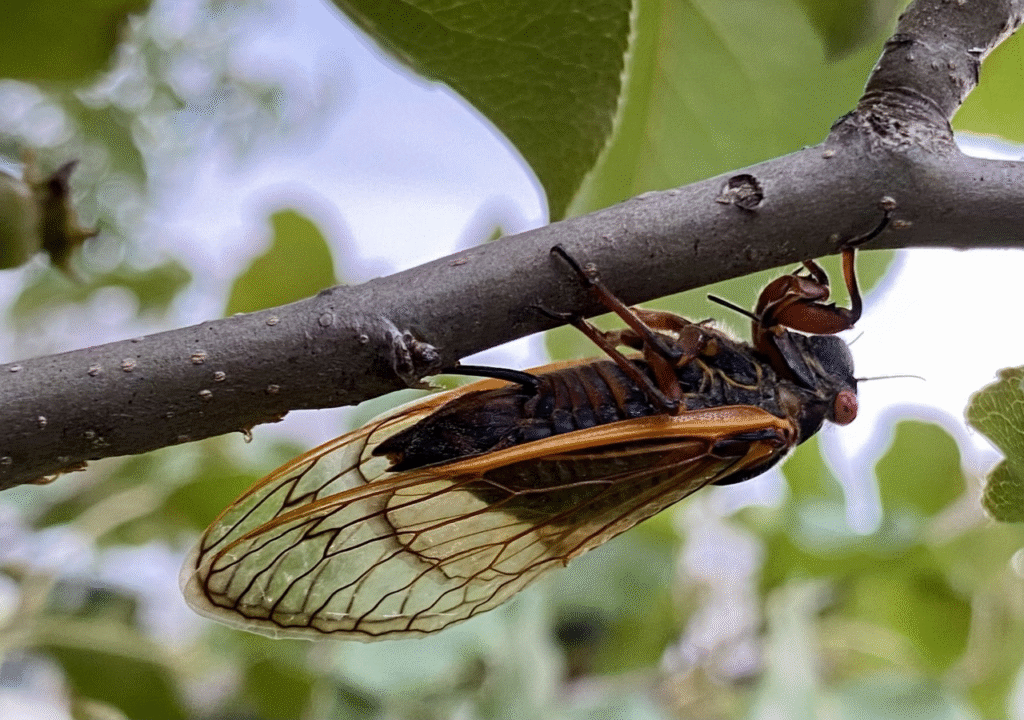

By: Andrew L. Loyd, Matthew A. Borden, Caitlin A. Littlejohn, Chad M. Rigsby, Beth Brantley, Mark Ware, Cory McCurry and Kelby Fite

Arboriculture & Urban Forestry Vol. 51, Issue 3

Below, we’ve curated the latest news and insights from trusted sources across the industry. Stay updated with these key highlights.

Trade Journal Articles

By: Kelli Rodda/ NurseryMag April 2025

Scientific Journal Articles

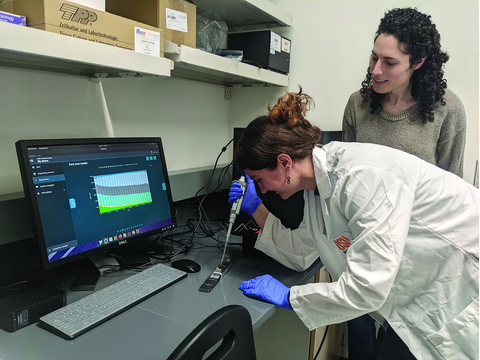

By: Ryan Hill; Lloyd Nackley; Marcelo Moretti

Journal of Environmental Horticulture (2025) 43 (1): 41–48.

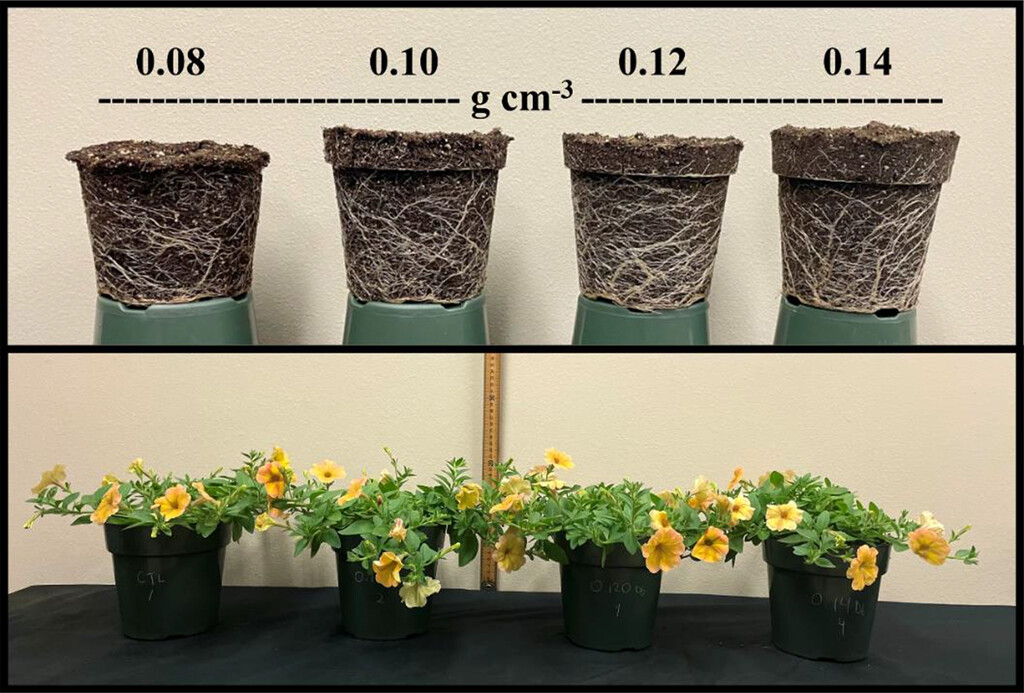

By:Asmita Paudel; Macie Sanders; Youping Sun; Xin Dai

Journal of Environmental Horticulture (2025) 43 (1): 49–55.

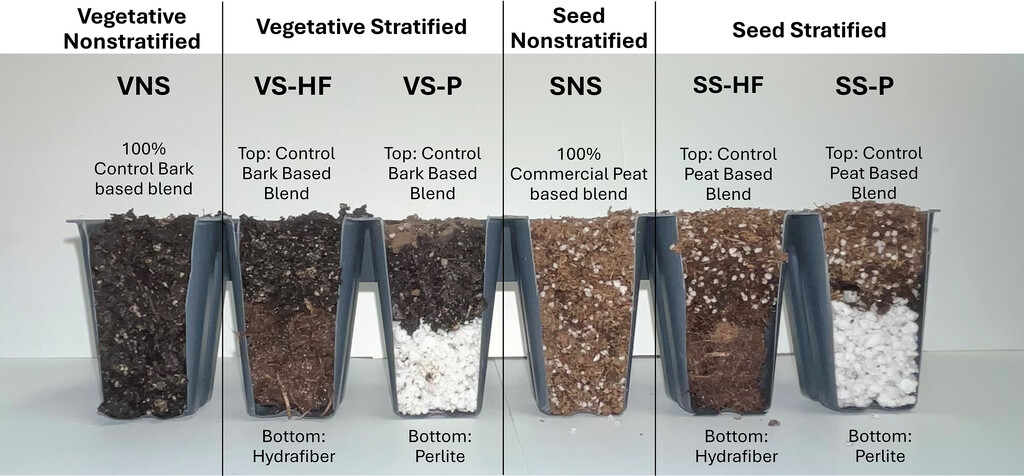

By: Milon Chowdhury Oliver Watson Uttara C. Samarakoon James E. Altland, Joanna Moine

HortScience Volume 60: Issue 5

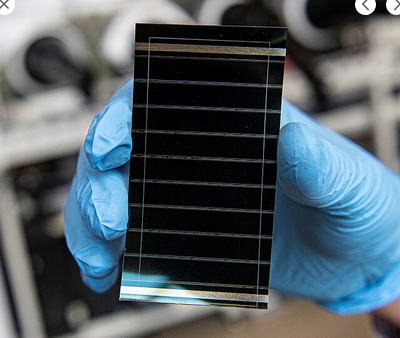

By: Harrison A. Meekins Paul R. Fisher Jonathan D. Judy , and Kevin M. Folta

HortScience Volume 60: Issue 5

Below, we’ve curated the latest news and insights from trusted sources across the industry. Stay updated with these key highlights.

Trade Journal Articles Scientific Journal Articles

By: Nadav Nitzan, Uri Adler, Hezi Goren, David Silverman and Tzion Decco / HortScience Vol 60: Issue 3

By: Daniel M. Dlugos, William C. Bridges, and Steven N. Jeffers / HortScience Vol 60: Issue 3

By: Andrew H. Jeffers, Bridget K. Behe, Michael Vassalos, William C. Bridges, and Sarah A. White / HortTech Vol 35: Issue 2

By: Maureen Thiessen, and Jeb S. Fields / HortTech Vol 35: Issue 2

Below, we’ve curated the latest news and insights from trusted sources across the industry. Stay updated with these key highlights.

Trade Journal Articles

By: Lloyd Nackley & Jeb Fields / NurseryMag Feb 2025

By: Neville Stein / NurseryMag Feb 2025

By: Patrick Alan Coleman / NurseryMag Feb 2025

By: Heather Stoven & Neil Bell / Digger Feb 2025

Scientific Journal Articles

By: Ihsanul Khaliq, Herve F. Avenot, Anton Baudoin, Leonard Coop and Chuanxue Hong / Science Reports Vol 14

By: Julie A. Herchkowitz, MAckenzie G. Dey, Royal Heins and Bruce Bugbee / HortScience Vol 60: Issue 3

By: Mingying Xiang, Marco Schiavon, Pawel Orlinski, and James H. Baird / HortTech Vol 32 : Issue 2

Below, we’ve curated the latest news and insights from trusted sources across the industry. Stay updated with these key highlights.

Trade Journal Articles Scientific Journal Articles

Helping People. Growing Plants.