Highlights

- Nurseries grow a wide variety of species and use many different crop production methods which can make effectively scheduling irrigation difficult.

- Mini-lysimeters are devices that measure evapotranspiration (ET) via a change in weight of a containerized crop.

- Mini-lysimeter controlled irrigation has shown to reduce water use and conserve nutrients while producing plants of marketable size and quality.

The need for sensor-controlled irrigation

Irrigation scheduling for nursery is complex due to the wide variety of species grown, the variety of pot sizes, the differences in growing media, and differences in environmental conditions (i.e. greenhouses, hoop-houses, field nurseries, or use of shade cloths). These factors all influence the specific crop water requirements, making it difficult to determine a generalized irrigation solution. As such, irrigation scheduling is commonly based on grower intuition and experience. For example, it is common for an experienced grower to pick up pots as they walk through a can-yard to get a feel for the weight and irrigation need. With funding support from the ODA-OAN research program, we sought out to develop an automated sensor-controlled irrigation system that is based off container weight, referred to as a mini-lysimeter controlled irrigation system.

What are lysimeters?

Lysimeters are devices that directly measure crop evapotranspiration (ET), which is the transfer of water from the soil to the atmosphere through plants by transpiration, and from the soil by evaporation. Lysimeters consist of a tank filled with soil and crop that is placed on a scale. Any change in weight of the tank is a direct measure of water moving in or out of the system. This provides a direct measurement of water consumption from the tank’s boundary, which can be used to inform irrigation scheduling. Lysimeters have historically been used in agronomic crops like wheat, alfalfa, or legumes. However, they can be scaled down for use in nursery and greenhouse crops, which are often referred to as mini-lysimeters (Fig. 1). You can read more about mini-lysimeters and their many applications in our recent publication.

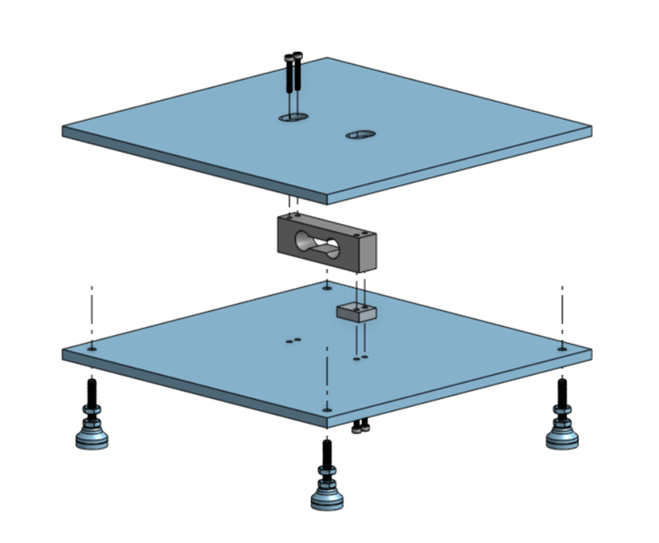

System Design The mini-lysimeter controlled irrigation system at the NWREC consists of 16 mini-lysimeters. They are suitable for measuring up to 10kg (22 lbs.), which can accommodate up to a 3-gal container (Fig. 2). The mini-lysimeters are hooked up to a Campbell Scientific CR1000X data logger (Campbell Scientific Inc, Logan, UT) using a multiplexer. The system is programmed to trigger irrigation for a zone based on the average container weight. This ensures that the applied irrigation is representative of the variability between containers, such as differences in the water holding capacity of the media, and irrigation uniformity. A guide detailing the design, calibration, and performance of the mini-lysimeter controlled irrigation system and can be found here.

System Performance When mini-lysimeter controlled irrigation is compared to traditional irrigation methods (i.e. irrigation on a timer), it has shown to use less water while producing plants of equal size and quality. Read more about this study here. Mini-lysimeter-controlled irrigation also responds more effectively to the seasonal and daily variations in water demand, increasing irrigation frequency during hot and dry conditions, and foregoing irrigation during cooler days or after rain. This is particularly salient as extreme weather events become more frequent. Having another set of eyes (sensors) looking over your crops can help reduce losses from over- and under-watering.